River Pebbles Sand Making

Результат проектирования

According to customer needs

Материал

River pebbles

Заявление

It is suitable for construction applications in cement concrete, asphalt concrete and various stabilized soil, and also for highway engineering applications in road, tunnel, bridge and culvert, etc.

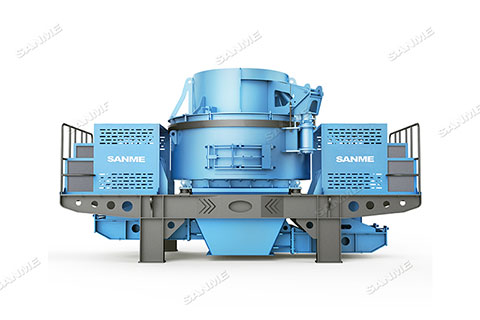

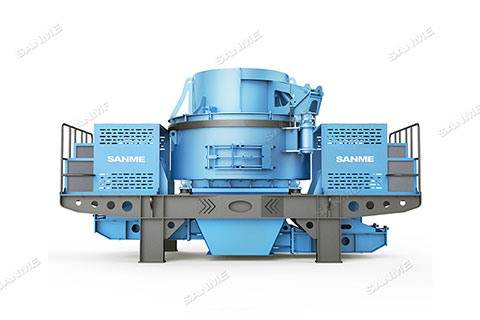

Оборудование

Cone crusher, sand making machine, sand washer, vibrating feeder, vibrating screen, belt conveyor,

Introduction of pebbles

Pebble, a kind of natural stone, is mainly from the pebble mountain which is raised from ancient riverbed because of the earth's crust movement millions of years ago. The formation of pebble undergoes continuous extrusion and friction of flood and running water. Pebble is usually smooth under action of wave and flowing water and buried under the earth surface with sand.

The river pebbles resource in China is abundant, the main chemical composition of gravel is silicon dioxide, secondly it is composed by small amount of iron oxide and trace elements such as manganese, copper, aluminum, magnesium and compound, it has natural stone features of hard quality, compression, wear-resistance and anticorrosion, it is an ideal material for building application. Currently gravel sand making production lines are continually built all over the country, which guarantee the supply of quality aggregate for national construction projects.

Basic process of pebbles sand making plant

The pebbles sand making process is divided into four stages: coarse crushing, medium fine crushing, sand making and sieving.

The first stage: coarse crushing

The pebbles blasted from the mountain is fed uniformly by the vibrating feeder through the silo and transported to the jaw crusher for coarse crushing.

The second stage: medium broken

The coarsely crushed materials are screened by vibrating screen and then conveyed by belt conveyor to cone crusher for medium crushing. The crushed stones are conveyed to the vibrating screen through a belt conveyor to sieve out different specifications of stones. The stones that meet the requirements of the customer's particle size are conveyed to the finished product pile through the belt conveyor. The cone crusher crushes again, forming a closed circuit cycle.

The third stage: sand making

The crushed material is larger than the size of the two-layer screen, and the stone is conveyed to the sand maker machine through the belt conveyor for fine crushing and shaping.

The fourth stage: screening

The finely crushed and reshaped materials are screened by circular vibrating screen for coarse sand, medium sand and fine sand.

Note: For the sand powder with strict requirements, a sand washing machine can be added behind the fine sand. The waste water discharged from the sand washing machine can be recovered by the fine sand recycling device. On the one hand, it can reduce environmental pollution, and on the other hand, it can increase sand production.

Flow chart of pebbles sand making plant

Feature introduction of river pebbles sand making plant

The sand making production line has the features of reasonable configuration, high automation, low operation cost, high crushing rate, energy saving, environmental protection, high capacity and easy maintenance, the manufactured sand conforms to national standard for construction sand, uniform grain, excellent particle size, well graded.

The equipments of the sand making production line are configured in accordance with the specification and output as well as application of the sand, we provide solution and technical support, and design the process according to the production site of customer, we make every effort to provide the most reasonable and economic production line for customers.

Техническое описание:

1. Этот процесс разработан в соответствии с параметрами, предоставленными заказчиком. Эта блок-схема предназначена только для справки.

2. Фактическая конструкция должна быть скорректирована в соответствии с местностью.

3. Содержание бурового раствора в материале не может превышать 10%, и содержание бурового раствора будет иметь важное значение для производительности, оборудования и процесса.

4. SANME может предоставить планы технологических процессов и техническую поддержку в соответствии с фактическими требованиями клиентов, а также может разработать нестандартные вспомогательные компоненты в соответствии с фактическими условиями установки клиентов.